| ADVANTAGES | VALUE IN USE |

|

Density and weight reduction |

Volume displacement by low density functional filling material |

|

Increased stiffness |

Due to high compressive strength and optimum filling of interspacial voids |

| Improved impact resistance |

Owing to its capacity to absorb and disperse energy within the binder matrix |

| Resin extension |

Less resin or binder needed due to low surface area and spherical geometry of particles |

| Reduced shrinkage |

Resulting from resin (binder) extension and particle size distribution |

| Reduced warpage (dimensional error) |

Due to improved dimensional stability, reduced binder and less shrinkage |

| Improved thermal insulation |

Ceramic composition and hollow structure enhances low thermal conductivity |

| High temperature resistance |

High melting point, non-combustible nature and stability at high temperatures |

| Optimised pigmentation |

Reduces white pigments costs and also formulation weight |

| Friendly water based formulas |

Neutral pH, resulting in less or no need for coated pigments and neutralisers |

| Improved durability |

Enhanced corrosion resistance and UV stability |

| Environmentally friendly |

Eco-friendly alternative to polymer based spheres / beads |

| Easy formulation |

Simple dispersion and incorporation into existing or new formulas |

Summary of Benefits

Adding value throughout the life cycle of end products

| Lower formulation costs |

Through resin extension and lower weight products |

| Transport and packaging costs |

Lighter final product weight & less expensive packaging materials needed |

| Lower labour and installation costs |

Easier handling of materials during production and faster and lighter to install components |

Key Properties

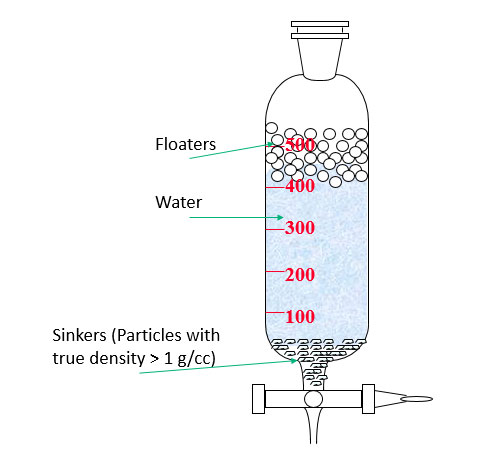

FUNCTIONAL LOW DENSITY

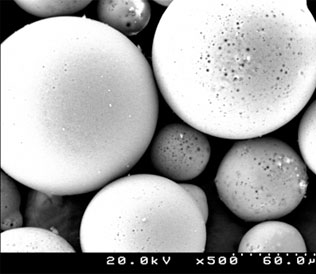

- Physical form of a free flowing powder

- Low bulk density of 0.40 g/cc

- Hollow structure

- With a partial vacuum inside

- Relative Density 0.8 g/cc

- Particle size 20 – 500 microns (different grades available)

- Over 94% floaters by volume

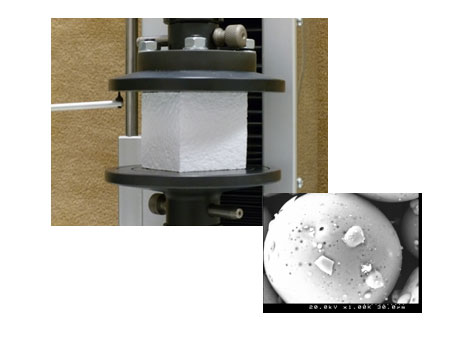

HIGH COMPRESSIVE STRENGTH

- Isostatic pressure tests show over 70% rate of particle survival at 4,800 psi (33 MPa)

- This is typically over 30% greater than other microspheres of similar density

- And 20 times higher than expanded glass fillers

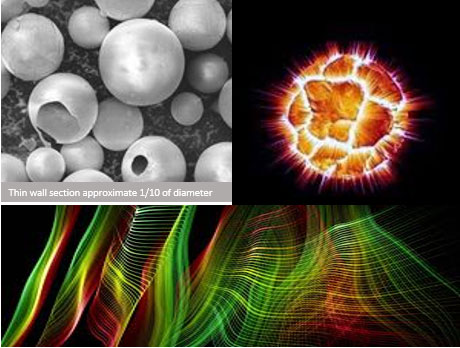

THERMAL RESISTANCE

- Industry leading melting point at over 1700⁰C

- Higher alumina content

- Lower iron oxide content

- Very low rate of thermal expansion (d) 8 x 10-6

- Super low conductivity of 0.1 W/m / ⁰C

- Thermal insulation due to the thin wall section encapsulating a hollow (near vacuum) core

CHEMICALLY INERT

- Due to its ceramic nature, E-SPHERES® are an extremely unreactive substance

- Resistant to most known chemicals such as solvents, organic chemicals, water, acid or alkalis

- Compatible with both waterborne and solvent based resin systems

- Neutral pH makes it cost effective and easy to use to formulate coatings and plasters

NON DANGEROUS GOODS

E-SPHERES® have undetectable levels of crystalline silica/quartz (at the present detection limits for bulk silica of 1%) & are classified as a non-hazardous substance.

They are also:

- Non combustible

- Non toxic

- Non flammable

- Non reactive

- Non corrosive

GEOMETRY & LOW ABSORPTION

- Spherical shape maximises filling properties (volume) and minimised area of contact

- For example: less resin to wet the surface

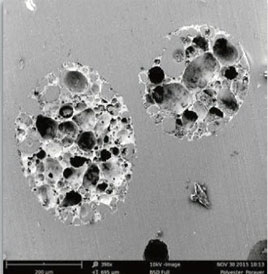

- This is an advantage against most ground fillers or foam type glass spheres

- Very low absorption optimises its resin extension qualities

E-SPHERES® SL Series: Non absorbent and optimal geometry.

Expanded glass: random shape and porous structure, diminishing its filling properties.

COLOUR

- E-SPHERES® SL Series are whiter than any other HCM in the market thanks to their unique chemical properties

- Also whiter than most lightweight fillers

- Potential reduction of cost & weight due to less white pigments needed in formulations

- Less TiO2 required

A world of possibilities

E-SPHERES® are an incredibly versatile additive, which also add value and improve performance of engineered materials and products.

Contact us for more information about how E-SPHERES® could enhance your technologies.